What is Lean Six Sigma?

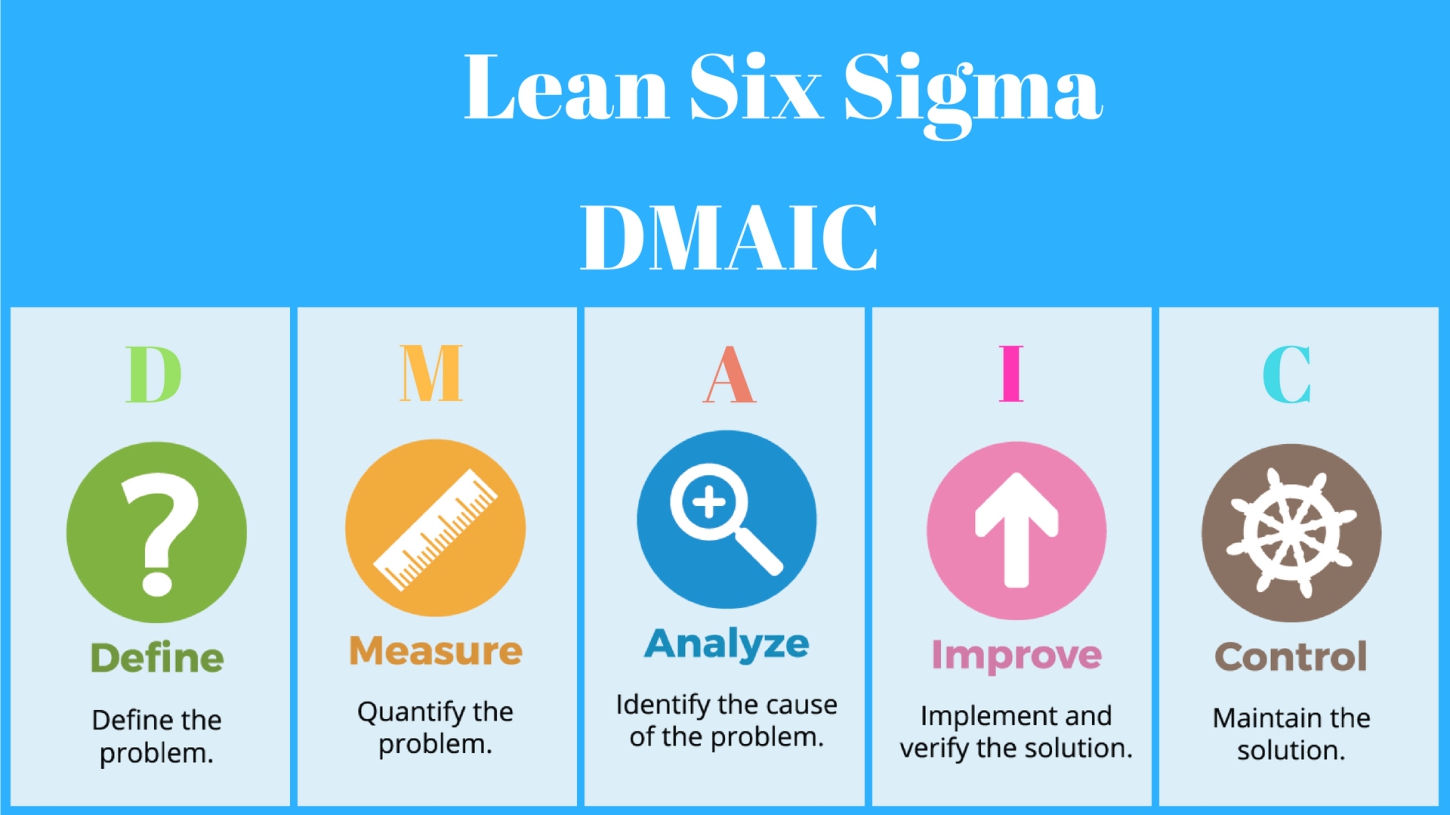

Lean Six Sigma is a fact-based, data-driven philosophy of improvement methodology which is focused on defect prevention rather than defect detection. It is a combination of two different powerful process improvement methodologies, (1) Toyota's Lean Manufacturing philosophy and, (2) Motorola's Six Sigma management strategy. It is a data-driven approach to increase profit, the satisfaction of the customer, and improves effectiveness and efficiency. This is a team-focused managerial approach that seeks to improve performance by eliminating wastes and variations.