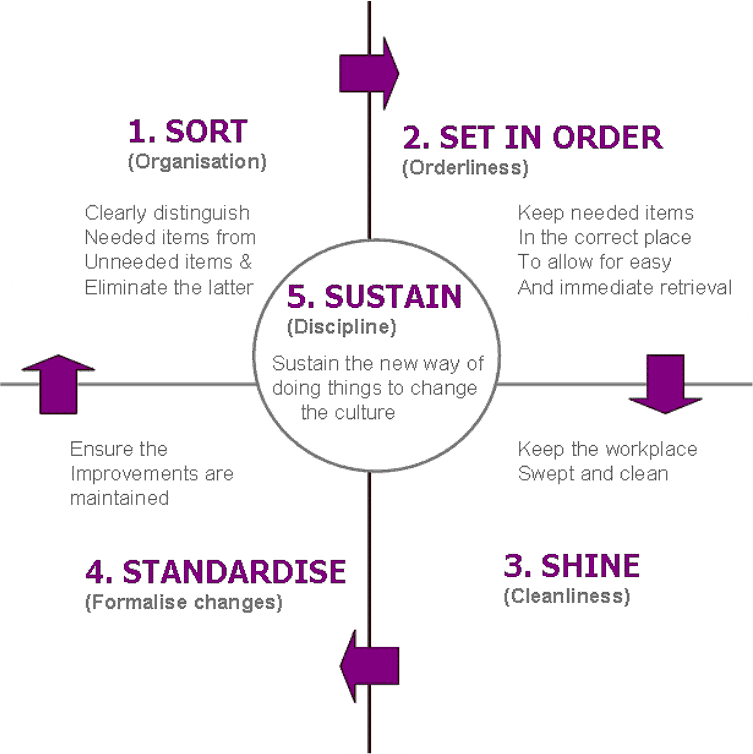

Getting Organized With 5S: Sort, Set, Shine, Standardize, Sustain

The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste. There are five steps in the system, each starting with the letter S. By providing a systematic framework for organization and cleanliness, 5S helps facilities avoid lost productivity from delayed work or unplanned downtime.

The philosophy of 5S represents a way of focusing and thinking in order to better organize and manage workspace, specifically by eliminating the 8 wastes as defined by the Lean Manufacturing system. It is one of the most widely used and fundamental components of Lean Manufacturing. Its simple, common-sense application is highly effective and reliable as a stabilizing force in Lean strategies.

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally. The 5S philosophy applies in any work area suited for visual control and lean production. The 5S condition of a work area is critical to employees and is the basis of customers' first impressions.

5s Management